How Long Does It Take to Break Even on a Screen Protector Vending Machine?

Discover the real ROI of a screen protector vending machine. Learn how automation cuts break-even time to just 3-6 month...

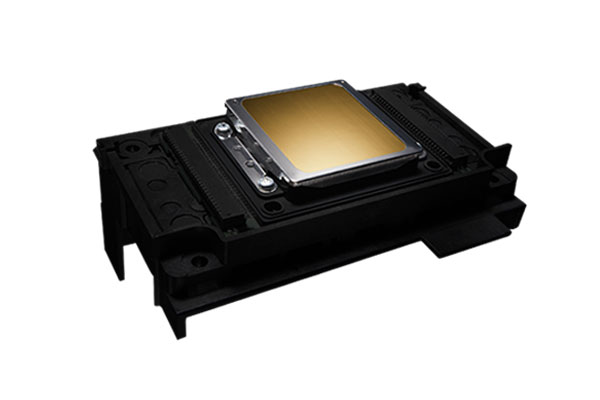

Every time a customer walks away with a new phone case, they are holding a physical representation of your service in their hands. The printhead is the component that makes that moment possible, turning a digital design into a durable, high-quality accessory that stays with them every day.

This guide breaks down the practical differences between mainstream options to help you choose the right setup for your production goals and keep your business running smoothly.

When you begin evaluating printheads, you will find that the market is primarily divided between versatile entry-level heads and precision-engineered industrial nozzles. The primary distinctions lie in the physical architecture, the number of active nozzles, and how well the materials resist the chemical wear caused by high-viscosity UV inks.

Nozzle Architecture: You will find that the I-series utilizes PrecisionCore MicroTFP technology, offering 20% to 30% higher accuracy and a significantly longer service life than older architectures.

Physical Width: Professional heads like the I1600 and I3200 provide you with an effective printing width of 33.8 mm, while the TX800 and XP600 / F1080 are limited to 25.4 mm.

Resolution Density: If you require extreme detail, industrial heads offer a higher mechanical resolution of 300 npi per row, compared to the 180 npi found in entry-level models.

Weight and Stability: You can expect more stability during high-speed movements from professional nozzles, which weigh 80g–82g, compared to the lighter 60g consumer-grade heads.

| Feature | Epson TX800 | XP600 / F1080 | Epson I1600 | I3200-A1 |

|---|---|---|---|---|

| Approx. Price | 400 RMB | 800-1,500 RMB | 5,000-7,000 RMB | 8,000-9,000 RMB |

| Nozzle Rows | 6 Rows | 6 Rows | 4 Rows | 8 Rows |

| Nozzle Count | 1,080 | 1,080 | 1,600 | 3,200 |

| Resolution (NPI) | 180 npi / row | 180 npi / row | 300 npi / row | 300 npi / row |

| Droplet Volume | 4.5–40 pl | 4.5–40 pl | ~5 pl (Binary) | 6–12.3 pl |

| Print Width | 25.4 mm | 25.4 mm | 33.8 mm | 33.8 mm |

| Frequency (kHz) | 46 kHz | 46 kHz | 43.2 kHz | 21.6–43.2 kHz |

| Ink Viscosity | 3–5 mPa·s | 3–5 mPa·s | 6–12 mPa·s | 6–12 mPa·s |

| Weight | 60g | 60g | 80g | 82g |

If you are starting a new project, the TX800 and XP600 / F1080 series offer a functional entry point without requiring a massive upfront investment. You can take advantage of their versatility, as they are compatible with a wide range of inks, including UV, eco-solvent, and water-based dyes. This flexibility allows you to experiment with various materials, although these heads are most commonly used in entry-level UV units where managing startup costs is the priority.

While the lower price point of these heads is attractive for your initial budget, you will need to commit to a more rigorous maintenance schedule to ensure consistent results.

Service Life: You can generally expect stable performance for 3 to 6 months in an active vending environment before these heads show signs of wear.

Nozzle Layout: With 1,080 nozzles in 6 rows, these heads provide enough resolution for standard graphics but may fall short if your designs require ultra-fine text.

Color Options: You have high flexibility with the 6-channel structure, which supports CMYK plus specialty channels for your white ink or varnish layers.

Ink Flow and Maintenance: These heads handle lower viscosity inks, which flow easily through the system but require you to perform more frequent cleaning cycles to prevent the nozzles from drying out during idle periods.

When you move into the professional tier, both the Epson I1600 and I3200 set the standard for UV printing in customized retail. They share several high-performance traits that you can rely on, including PrecisionCore MicroTFP technology and a 33.8 mm printing width that covers more surface area in a single pass. Most importantly for your business, both support high-gap printing of up to 9mm, allowing you to maintain sharp focus around camera bumps and curved edges while protecting your nozzle from physical damage.

Despite their shared architecture, you will find that the I3200 serves as a much more powerful engine than the I1600. The differences you experience will manifest in both the fine detail of your cases and your overall machine output.

Epson I1600: This head provides you with 1,600 nozzles across 4 rows. It uses a refined 300 npi per row density, delivering a balanced resolution that is perfect for high-definition photography on standard case surfaces.

Epson I3200: For your most demanding designs, the I3200 packs 3,200 nozzles into 8 rows, nearly doubling the available firing points. It maintains the same high 300 npi per row but allows for much higher ink density in a single pass, making it your best choice for rendering micro-logos with absolute clarity.

Epson I1600: You can view this as a steady industrial workhorse, ideal if your business prioritizes a lower cost-per-head while still requiring professional UV durability and a 33.8 mm print width.

Epson I3200: This acts as your high-speed powerhouse, firing more ink droplets per second thanks to its 8-row configuration. This efficiency is vital if you expect to handle back-to-back orders in high-demand environments where minimizing the time-per-case is your top priority.

Your customers pay for personalization, and the visual sharpness of the final product determines the perceived value of your service. Image resolution is the result of the physical nozzle density (npi) of your head and the mechanical stepping accuracy of your machine’s tray.

You will find that nozzle spacing directly corresponds to the mechanical resolution your machine can achieve. The smaller the spacing (higher npi), the higher the physical precision in the longitudinal direction. Higher density helps you provide:

Crisp Details: Your logos and small text will appear sharp, ensuring your branding looks professional.

Seamless Curves: Higher nozzle counts eliminate the jagged staircase effect on curved lines that can make your premium designs look cheap.

Legible Fonts: You can ensure even the smallest micro-fonts remain readable, which is essential if your cases feature modern, text-heavy graphics.

When your customers upload personal photos, the density of your nozzles determines how natural the final print looks.

Smooth Gradients: Higher npi heads allow you to offer seamless color transitions in skin tones without visible banding.

Premium Texture: By increasing the dots per inch (dpi), you minimize the grainy or sandy texture that often frustrates users of lower-quality machines.

Functional Accuracy: For designs involving QR codes, the 300 npi or higher capability of industrial heads ensures your functional elements scan correctly every time.

Serving your customers efficiently is the primary driver of your daily revenue. Firing frequency, measured in kilohertz (kHz), dictates how many ink droplets your nozzles can eject per second. This technical limit determines how fast your printing carriage can travel while still maintaining a high-quality image.

A high firing frequency allows you to maintain resolution at higher velocities. For example, the I3200 series can reach up to 43.2 kHz, enabling your printhead to scan across the phone case faster than entry-level models. This advantage allows you to:

Increase Your Hourly Output: More nozzles combined with high frequency mean you can complete more cases during short, high-traffic windows.

Improve Layer Efficiency: You can apply white bases and protective varnish layers more rapidly, which is essential for the multi-layer textures popular on high-end phone cases.

Reduce Customer Wait Times: A faster phone case printing process improves your user experience and prevents long queues from forming in front of your machine.

You must consider the longevity of your printhead as a major factor in your long-term operating expenses. Choosing the right architecture directly influences how often your machine requires manual intervention.

You should be aware that the TX800 and XP600 / F1080 are built with lighter materials (60g) that may degrade faster when exposed to abrasive UV pigments. Because these were originally consumer-grade heads, their internal seals are more susceptible to the corrosive nature of high-viscosity UV inks. In an active vending scenario, you can expect these heads to provide stable performance for roughly 3 to 6 months before you need to replace them.

In contrast, professional industrial nozzles like the Epson I1600 and I3200 are manufactured with specialized materials specifically for high-viscosity UV applications (6–12 mPa·s).

Advanced Waveform Control: These heads feature electronics that maintain your ink fluidity, preventing clogs during the idle periods common in vending machine operations.

Increased Longevity: By resisting chemical degradation and employing PrecisionCore technology, I-series nozzles offer you a much longer service life, reducing how often you need to perform on-site technical visits.

Reliable Startup: Superior waveform management ensures your machine is ready to print immediately, so you don't waste time or ink on excessive cleaning cycles.

Your choice of a printhead should be based on a comprehensive assessment of your production goals and technical overhead.

For operators testing a new market or working with a limited initial budget, the TX800 or XP600 / F1080 offers you the quickest path to launch. However, you must expect a shorter lifespan and more frequent manual maintenance. If your business model does not include on-site technical staff, you may find that your lower upfront cost is quickly negated by service expenses and lost sales during downtime.

When your machine is out of order, you lose 100% of your revenue for that period. The I3200 series is designed to protect your income through industrial-grade uptime.

Speed as an Asset: The 33.8 mm width and 3,200 nozzles allow for faster production, helping you capture more sales during peak traffic hours.

Value-Added Precision: Higher density (300 npi) enables you to produce photographic cases that can justify a higher retail price for your customers.

Logistical Stability: Industrial heads reduce your technical burden, making them your preferred choice if you plan to scale a large fleet where frequent maintenance is a logistical challenge.

Deciding on the right printhead involves a careful evaluation of how speed, resolution, and maintenance costs align with your specific production goals. While entry-level nozzles offer an accessible starting point for exploring new markets, industrial-grade options provide the durability and precision required for high-volume operations. Understanding how these components function allows you to set clear expectations for your print quality and operational uptime as your business scales.

Because these technical performance factors directly determine your business success, Gobear engineers every phone case printing vending machine to harmonize high-performance nozzles with stable, autonomous hardware. We design our systems to take the guesswork out of customized retail, allowing you to focus on growth while our technology handles the precision. Our hardware solutions are specifically calibrated to match your production goals, ensuring professional results for every customer.

Ready to transform your vision into a high-performance reality? Partner with us today to lead the future of automated customized retail.

Tell us about your business goals, and our experts will provide a tailored solution and a detailed profitability report. Let's start building your new revenue stream together.